Budweiser and BETC

Cooling PerishablesWithout Electricity

A below-ground cooler empowers entrepreneurs and protects products

Service and Offer

Studio

Sustainable innovation

The growing demand for energy to fight the effects of global warming is a real problem in hotter countries. In climates where temperatures can exceed 50°C, damage to power infrastructure is probable, compromising the viability of perishable products.

Budweiser is committed to drastically reducing its scope 1, 2 and especially 3 emissions (largely linked to the electrical consumption of refrigerators). Pursuing this mission, it has updated an ancestral technique that guarantees sustainable access to refrigeration without electricity.

frog and BETC have joined forces to help Budweiser develop a low-tech, self-sufficient refrigeration solution that is open-source and accessible to as many people as possible. The challenge of this system is to achieve sufficiently low temperatures (6°C) to preserve foodstuffs for a long time without the need for electricity, all while boosting the regional economic and social network by exploiting local know-how and materials.

This collaboration showcases the value of adopting a low-tech approach to developing products and services that are accessible to all. At frog, we design solutions based on the economy of means to keep pace with today's environmental and social challenges.

Playing it cool

Project highlights

Methodology

in the makingChallenge

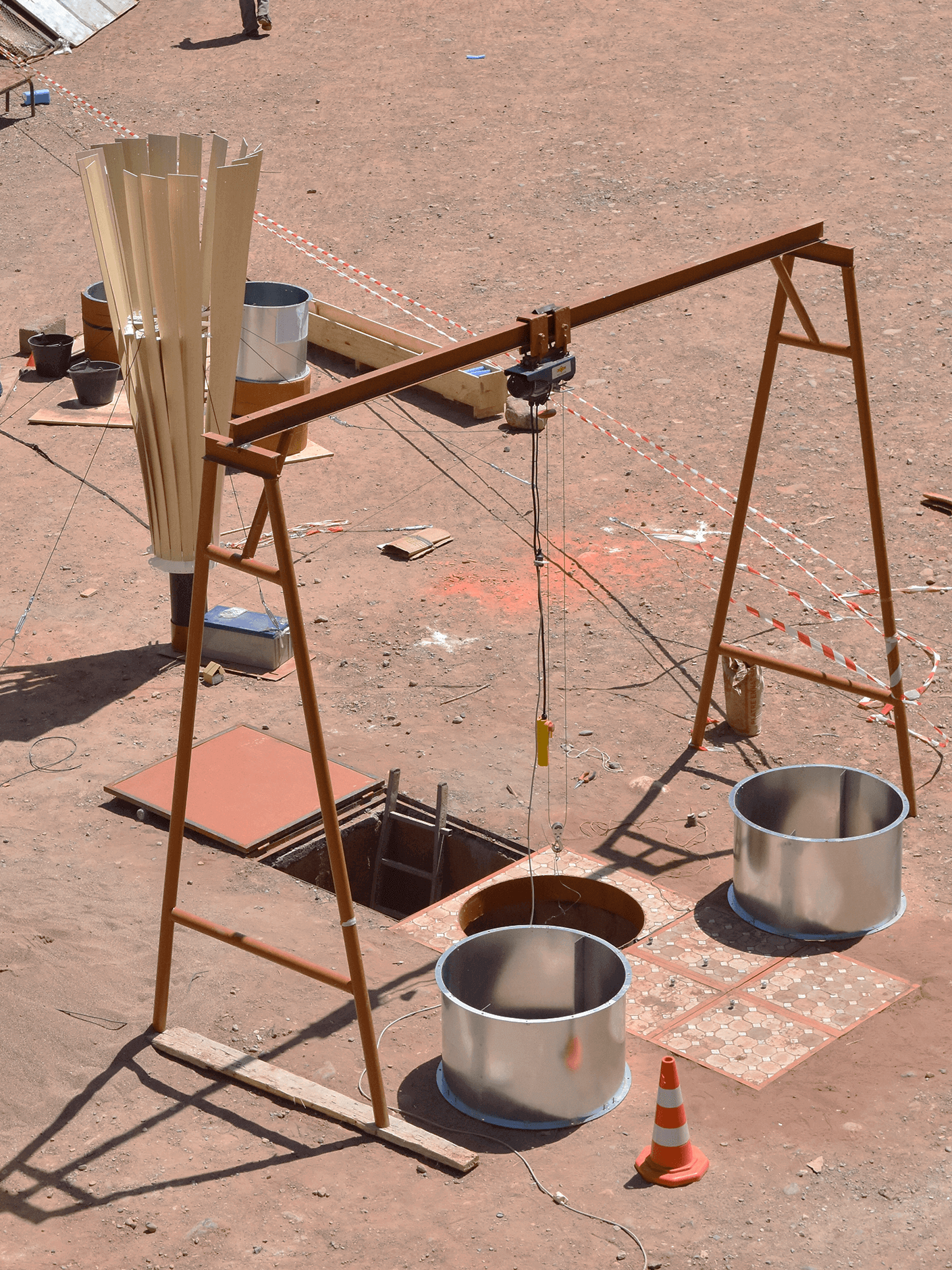

The goal of this collaboration was to assemble a multi-disciplinary team and work with partners (Capgemini Engineering and various local tradespeople) to design and deliver a cooling system that does not need power.

Low-tech and modular

Solution

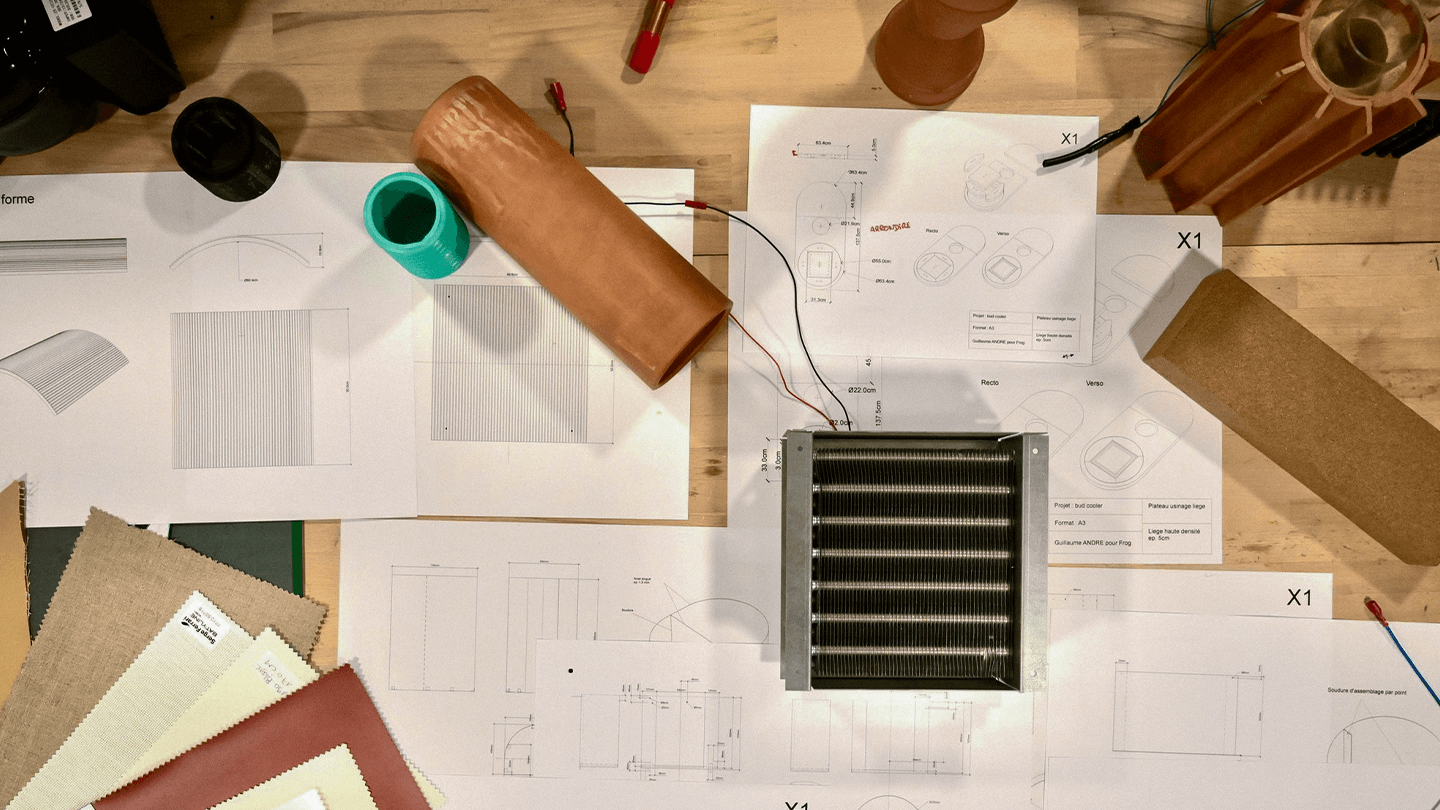

We updated the “Zeer Pot” technique (clay pot evaporation) with an underground thermal section, an above-ground system that promotes air flow and a swatch of solar cloth for more cooling applications.

Driving social impact

Outcomes

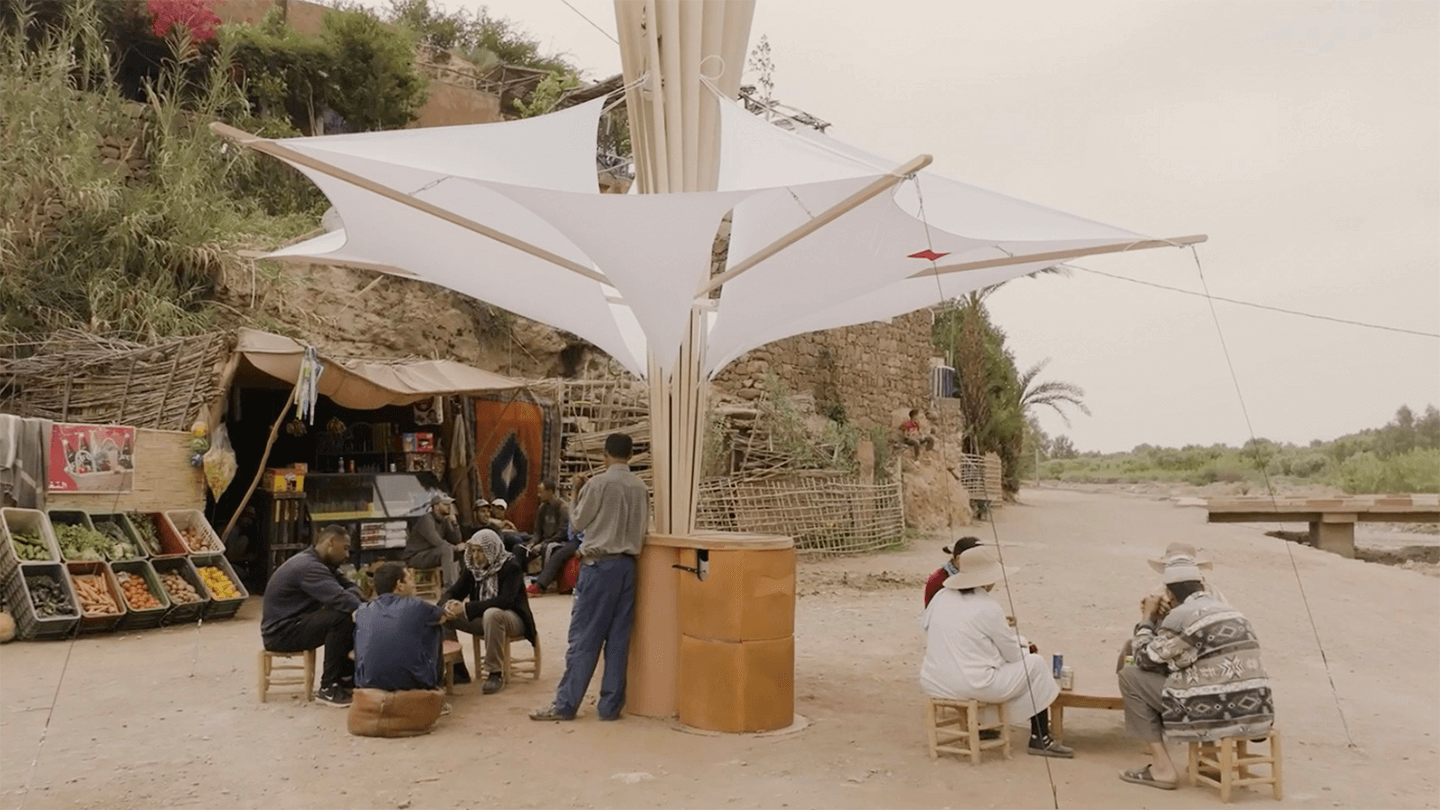

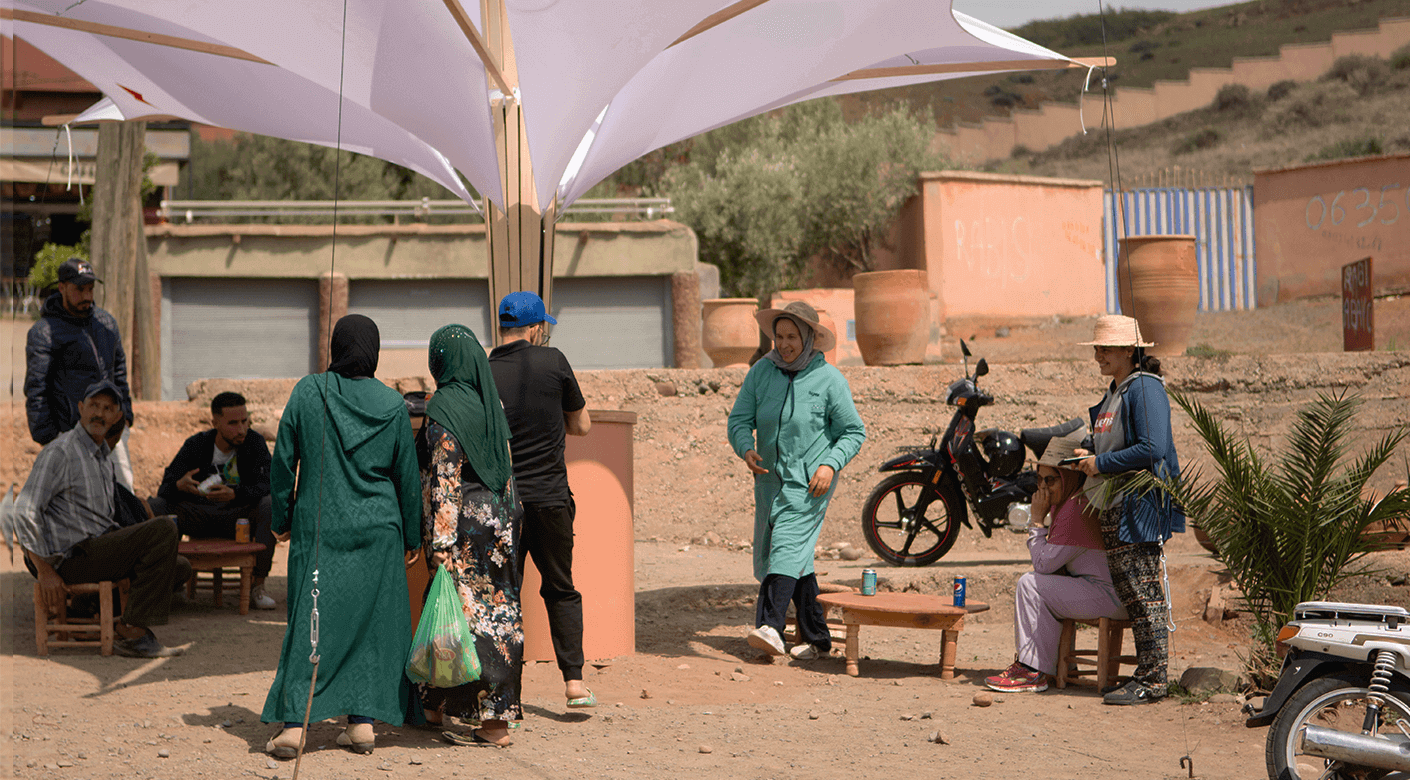

The cooler was successfully tested with locals in a Moroccan village, leading to a better understanding of the real needs of targeted populations and inspiration that feeds our ambition.

Two nested cylinders made of clay and galvanized steel.

Two nested cylinders made of clay and galvanized steel.

The system has become a popular meeting place in the village.

frog was a trustworthy partner with a real problem-solver mindset required for complex projects and for identifying the real challenges.

Low-tech to no-tech

This project's primary impact is social. Our goal is to provide regions most suffering from climate change the benefit of an essential human need: food preservation. Not only did we deliver a technique, but we also empowered entrepreneurs and stimulated business.

Budweiser plans to expand this project in several countries. To achieve this, the project needs to be low-tech and rely on the resource economy.

Low-tech solutions and technical credibility are highly compatible. We combined “quick and dirty” research with cutting-edge expertise and tools in thermodynamics and fluidics.

The simplicity and adaptability of our solutions guarantee autonomous operation and contribute to overcoming sustainability challenges.

Our low-tech solutions prove frugal and accessible products need not sacrifice quality and efficiency.